Where is the intelligent control of the solenoid valve group box specifically reflected?

Jun 04, 2025

Remote control: The solenoid valve group box can realize automatic adjustment of the gas source through remote control, which not only improves production efficiency, but also reduces the complexity of manual operation and ensures the continuous and stable operation of the production line. The intelligent control system can automatically adapt to production needs and realize dynamic adjustment of the gas source, providing strong support for the company's production optimization and cost control.

Timing control and sequence control: Modern solenoid valve control boxes have intelligent control functions, including remote control, timing control, sequence control, etc., which can flexibly meet different process requirements.

Automatic adjustment and fault warning: Combined with PLC time setting and sensor data, the system can automatically adjust the gas source flow and pressure, and trigger an alarm when the gas pressure fluctuates or the gas source is insufficient (as stated in the WeChat public platform "the intelligent monitoring system collects data in real time and automatically adjusts the state of the solenoid valve").

Data analysis and optimization: By collecting operation data, the system can analyze the efficiency of gas source use, optimize control strategies, and reduce energy waste (such as the WeChat public platform mentioned "avoid excessive gas supply and reduce energy costs").

Modularity and integration capability: The modular design supports functional expansion and is compatible with multiple communication protocols (such as HART, Profibus), which is convenient for integration with existing industrial systems (such as "modular design, compatible with traditional solenoid valves" in the Zhihu article).

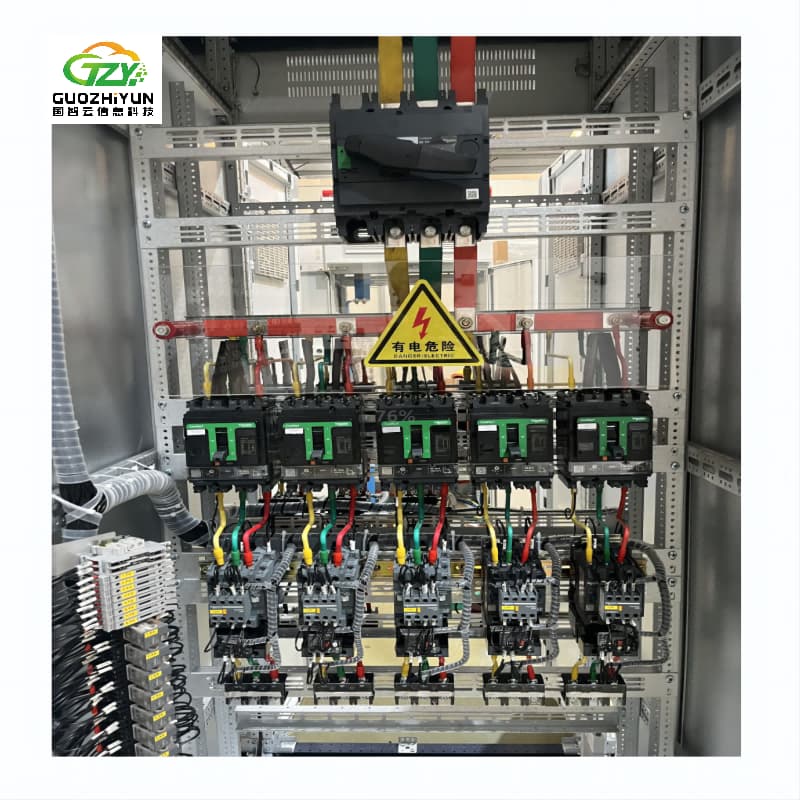

Real-time feedback and protection function: Through sensors or limit switches, the working status of the solenoid valve is monitored in real time and fed back to the control system or operator. At the same time, it has overload and short-circuit protection functions to prevent circuit faults from damaging the solenoid valve and control equipment.

Human-machine interface: Configure the human-machine interface (HMI) to facilitate operators to set parameters, monitor status and diagnose faults.

Data recording and display: Through the LCD display or communication interface, the working status of the solenoid valve is displayed in real time, and it has data recording function, which is convenient for fault diagnosis and maintenance.

Multi-channel control: Supports centralized control of multi-channel solenoid valves. One control box can manage multiple solenoid valves at the same time, simplifying the design and maintenance of the system.

Flexible installation method: Modular design, easy installation, support for multiple installation methods such as wall-mounted and floor-standing, adapting to the on-site space layout.

Service and Support:

We provide one-stop services from design, manufacturing, installation to commissioning, as well as comprehensive after-sales service and technical support to ensure the stable operation and production efficiency of pharmaceutical plant equipment.

During the implementation phase, the project team conducted comprehensive testing to ensure seamless interoperability between components. In the end, we created a responsive control system that not only meets the stringent requirements of biopharmaceutical production, but also improves overall operational efficiency. By simplifying the control architecture, the new system reduces the possibility of human error, speeds up troubleshooting, and minimizes downtime.