Comprehensive Guide to Selecting Low-Voltage Distribution Boxes: Core Parameters, Application Scenarios, and Selection Guidelines

May 14, 2025

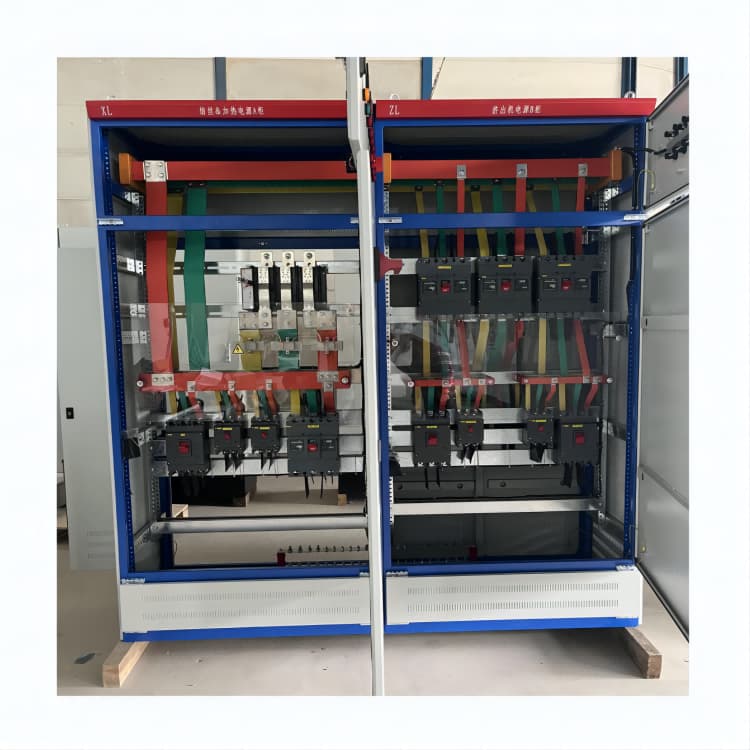

I. Low-voltage Distribution Box: The "Central Nervous System" of the Power System

The low-voltage distribution box is a power distribution device that integrates electrical components such as circuit breakers, contactors, and relays. It can achieve power distribution, switch control, and fault protection for electrical equipment. Its core advantages are as follows:

Flexible power distribution: It distributes electrical energy to multiple circuits as required, meeting the power demands of different equipment.

Safety protection: It is equipped with overload, short-circuit, and leakage protection devices to avoid electrical accidents.

Convenient management: It centrally controls the on-off of the circuit, simplifying the maintenance process of the power system.

II. Analysis of Core Parameters: Selecting the Right Product by Understanding the Specifications

Electrical parameters: Determining the "heart" performance of the equipment

Rated voltage: The main circuit is commonly 380V AC (suitable for industrial equipment such as three-phase motors), and some models support 660V AC. The auxiliary circuit covers 220V AC/DC, etc., and it needs to be matched according to the voltage of the control system.

Rated current: The range is from 400A (small distribution box) to 4000A (large power distribution system). For example, the rated current of the vertical bus system of the GCK series is 400-800A, and it needs to be selected by calculating according to the total power of the load.

Breaking capacity and withstand current:

Rated breaking capacity (e.g., 15kA for PGL1 type and 30kA for PGL2 type): It refers to the ability to quickly cut off the current during a short circuit. The higher the value, the stronger the safety.

Short-time withstand current (e.g., 80kA/1 second for the horizontal bus of the GCK series): It measures the ability of the equipment to withstand the instantaneous short-circuit current, ensuring that the equipment is not damaged during a fault.

Environmental parameters: The key to adapting to complex working conditions

Temperature and humidity: The normal operating temperature is -5℃ to +40℃, and the humidity does not exceed 50% (at 40℃). If the environment is humid (such as in basements or outdoors), a moisture-proof box should be selected.

Altitude and protection level: For indoor use, the altitude does not exceed 2000m. The protection level is above IP40 (preventing solid foreign objects and splashing water), and for outdoor use, it needs to reach IP54 or higher (preventing heavy rain and dust).

Structural design: The convenience of installation and expansion

Installation method: It supports surface-mounted on the wall, recessed installation in the wall (indoors), or floor-mounted, surface-mounted on the wall outdoors. It needs to be selected according to the space conditions.

Expandability: The modular design allows for flexible addition or reduction of circuits. For example, new circuit breakers or leakage protectors can be added to adapt to the expansion requirements of future loads.

III. Three Major Application Scenarios: Matching Functional Configurations as Required

Industrial manufacturing: Ensuring the stable operation of the production line

Scenario: Power distribution for equipment such as machine tools, fans, and conveyors in small factories and workshops.

Requirement: High rated current (such as above 800A) and strong breaking capacity (to deal with the impact current during motor startup). The GCK series or customized industrial-grade distribution boxes are recommended.

Commercial buildings: Efficiently managing diverse electrical equipment

Scenario: Power distribution for lighting, air conditioning systems, elevators, charging piles, etc. in shopping malls.

Requirement: Multi-circuit control (such as 10-30 circuits) and intelligent monitoring (real-time display of voltage/current). An intelligent distribution box with an RS485 communication interface can be selected for convenient remote management.

Infrastructure: A reliable choice for harsh environments

Scenario: Outdoor power distribution cabinets, municipal engineering, and new energy charging piles.

Requirement: High protection level (such as IP65 for water and dust protection) and corrosion-resistant housing (stainless steel material) to ensure long-term operation in humid, dusty, or salt spray environments.

IV. Purchase Guide: Pitfall Avoidance Points and Selection Skills

Clarify the load requirements:

Calculate the total power (kW) → Convert the rated current (I = P/√3/U/cosφ), and reserve a 20% redundant capacity to avoid overload.

Example: For a 30kW three-phase device, the current is approximately 57A, and a distribution box with a rated current of 80A can be selected.

<li style="color: rgba(0, 0, 0, 0.85) !important; fon