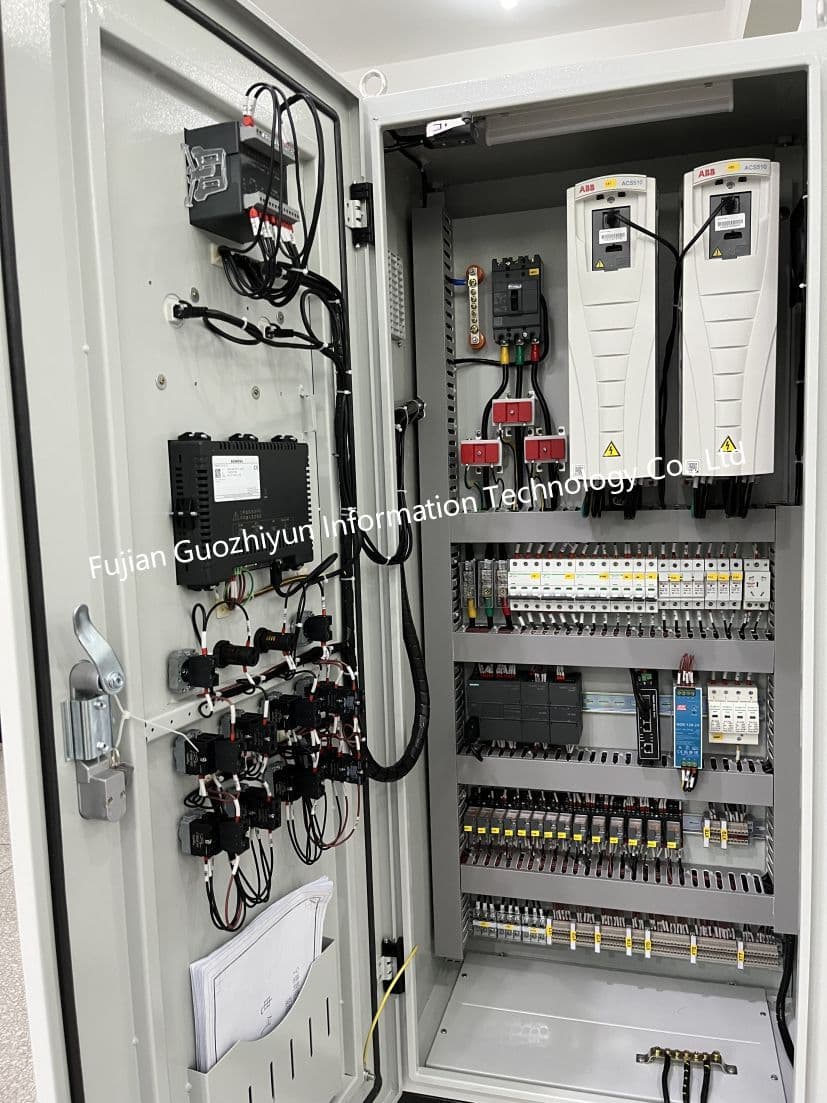

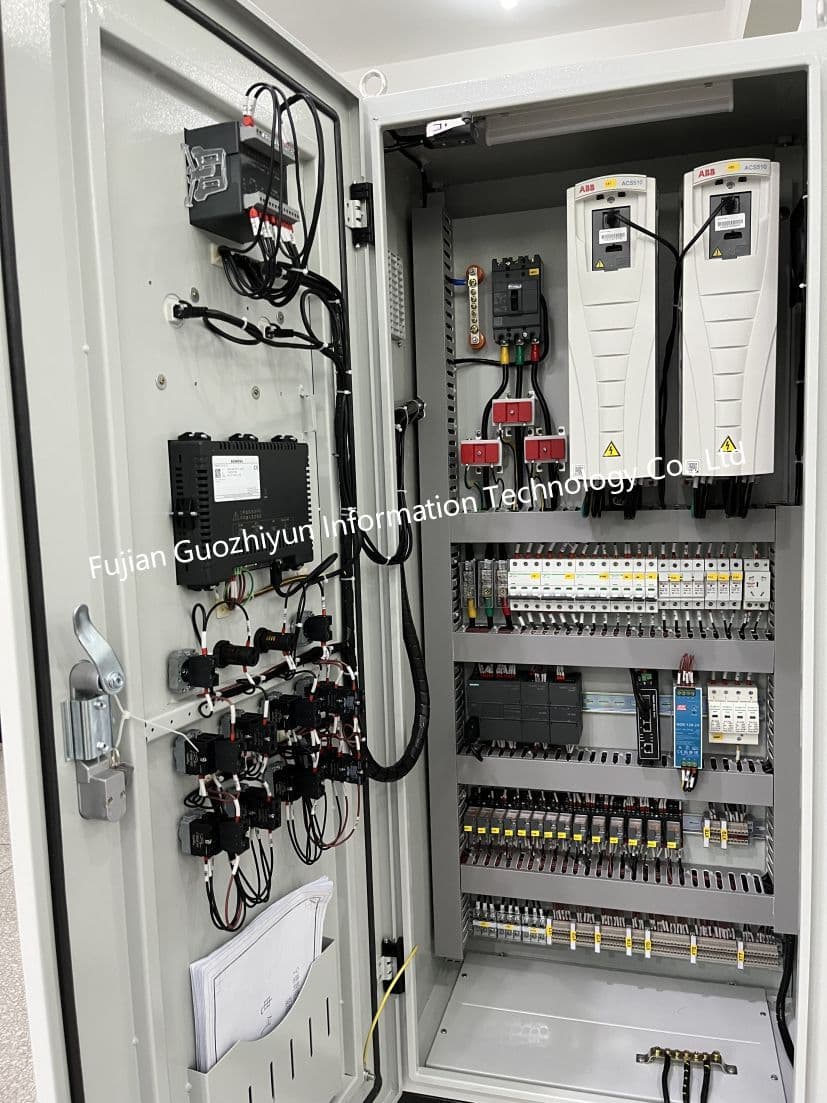

Our Variable Frequency Drive Panels are designed to provide a reliable and efficient solution for controlling the speed of industrial motors. The panels are equipped with high-quality variable frequency drives that allow for precise control of motor speed, reducing energy consumption and improving overall efficiency.

The panels are designed to operate in harsh industrial environments and are built to withstand the demands of heavy-duty applications. The Variable Frequency Drive Panels are easy to install and maintain, providing a convenient and cost-effective solution for industrial motor control.

I. Product Overview

The frequency conversion control cabinet is an advanced electrical device designed specifically for the control of industrial and civil equipment. Its main function lies in precisely adjusting the operating frequency of the equipment. Through this adjustment, it can not only significantly reduce energy consumption but also enable the equipment to start smoothly, effectively minimizing the damage to the motor caused by the large current during direct startup.

This control cabinet is equipped with a variety of functional modules. It has built-in analog input, which can be used for speed control or feedback signal reception; it integrates PID control to ensure stable system operation; it has a pump switching control function, suitable for constant pressure scenarios; it supports communication functions, facilitating system integration and remote monitoring; it has an application macro function, allowing parameter setting for different occasions; and it also supports multi - speed control to meet diverse working conditions.

With its powerful functions, the frequency conversion control cabinet can be widely applied to the automatic control of various scenarios, including water supply and drainage in industrial and agricultural production and various buildings, fire protection, spray pipe network pressurization, as well as cold and hot water circulation in HVAC systems, providing efficient and stable solutions for equipment operation in different fields.

II. Product Features

1. Energy Saving

Compared with motors controlled by traditional methods, motors controlled by frequency converters have significant advantages in energy saving. It can provide an economical operating state for the motor according to the actual demand for water injection and oil transportation, achieving an energy saving of 40%, greatly reducing energy consumption and saving substantial electricity costs for users.

2. Reduced Operating Costs

The operating costs of traditional motors consist of three components: initial procurement cost, maintenance cost, and energy cost. Among them, the energy cost accounts for approximately 77% of the total operating cost. By reducing the energy cost by 40% and also decreasing the impact on equipment during frequency conversion startup, which in turn reduces maintenance and repair requirements, the overall operating costs are significantly lowered, bringing long - term economic benefits to users.

3. Improved Pressure Control Accuracy

The frequency conversion control system has precise pressure control capabilities, enabling the pressure output of the motor to perfectly match the water injection volume required by the system. The output of the frequency - controlled motor changes with the change in motor speed. Due to the high precision of frequency - controlled motor speed, the pressure change of the pipe network system can be maintained within a range of 3 pisg (approximately 0.2 bar), effectively improving the quality of the working conditions and meeting the requirements of occasions with high - precision pressure control.

4. Extended Motor Service Life

The frequency converter starts the motor from 0HZ, and its starting acceleration time can be adjusted, which greatly reduces the impact on the electrical and mechanical components of the motor during startup, enhances the reliability of the system, and significantly extends the service life of the motor. In addition, frequency conversion control can effectively reduce the current fluctuation during unit startup. This fluctuating current can affect the power consumption of the power grid and other equipment, and the frequency converter can effectively minimize the peak value of the starting current.

5. Reduced Motor Noise

According to the working conditions of the motor, after installing frequency conversion speed regulation, the motor speed is significantly reduced, thus effectively reducing the noise generated during motor operation and creating a quieter environment for equipment operation.

III. Usage Requirements

1. Power Supply

It supports various power supply methods, including municipal power, self - supplied power grids, and diesel generator sets. The applicable power supply is three - phase AC 380V, with a voltage fluctuation range of - 10% to + 15% and a frequency of 50HZ.

2. Applicable Motors

General squirrel - cage asynchronous motors.

3. Starting Frequency

It can be started frequently, but it is recommended not to exceed 20 times per hour.

4. Protection Level

Two protection levels, IP41 or IP20, are available to meet the protection requirements of different environments.

5. Applicable Environment

• Altitude: not exceeding 2000 meters (derating is required when exceeding 2000 meters).

• Ambient temperature: between - 25℃ and + 40℃.

• Relative humidity: not exceeding 95%, without condensation.

• Vibration: less than 0.5G.

IV. Typical Applications

1. Constant Pressure Water Supply Control for Industrial, Domestic, and Fire Protection

In industrial production water supply, domestic water supply, and fire protection water supply systems, the frequency conversion control cabinet can achieve constant pressure water supply, ensuring stable water supply pressure, meeting the water demand of different scenarios, and at the same time saving energy and reducing operating costs.

2. Constant Temperature and Constant Pressure Control of Air Conditioning Cooling Water Circulation

Applied to the air conditioning cooling water circulation system, it can precisely control the water temperature and pressure, ensure the efficient operation of the air conditioning system, improve the cooling effect of the air conditioner, and reduce energy consumption.

3. Automatic Water Supply Control for Urban Square Musical Fountains

It provides automatic water supply control for urban square musical fountains. According to the rhythm of the music and the fountain design requirements, it precisely adjusts the operating frequency of the water pump, realizes diverse changes in the fountain water flow, and creates a magnificent fountain landscape.

The frequency conversion control cabinet, with its excellent performance, wide applicability, and reliable quality, is an ideal choice for equipment control in many fields. We are committed to providing customers with high - quality products and comprehensive solutions, helping customers achieve efficient, energy - saving, and stable equipment operation.